“From These Hills … ”

Midianite tent shrine found amidst ancient Negev copper mines. Recent excavations lead to new understanding of ancient mining technology; no evidence of King Solomon.

016

For almost two decades and still continuing, Israeli archaeologist Beno Rothenberg has investigated the Timna Valley—called in Arabic wadi Mene’iyeh and known to thousands of visitors as “King Solomon’s Mines”. At first Rothenberg came almost alone to this isolated spot in the Negev about 20 miles north of Eilat, but in recent years he organized an international team of miners, geologists, physicists, historians and engineers. Rothenberg and his team have probed slag heaps and smelting camps under a blazing sun that often reaches 120 degrees fahrenheit. In the past three years, Rothenberg penetrated seemingly endless ancient mine shafts and galleries.

Although as early as 1845, the British explorer, J. Petherick recognized the mining activities in the Timna Valley from piles of slag, and although in the 1930’s the American rabbi and archaeologist Nelson Glueck and a German scholar named Fritz Frank identified seven ancient smelting sites in the valley, no one reported ore deposits other than scattered surface nodules. Glueck dated the pottery which he found scattered about the site to the 10th century B.C., the century of Solomon. Glueck concluded that this must be the site of King Solomon’s mines and the source of much of his legendary wealth. It was a measure of Glueck’s confidence in his conclusion that he remarked, “For some reason or other 019the author of First Kings [in describing Solomon’s commercial activity] … failed to mention the fact that Solomon exported ingots of copper and tin and finished metal products … in trade for gold.”! (The Other Side of the Jordan, p. 120)

Rothenberg believes that as a result of his recent excavations, the modern legend that Timna was King Solomon’s mines has been destroyed. To replace this legend, Rothenberg offers a new understanding of ancient copper mining and metallurgy, and a perception of the people who mined there, including their tools, trinkets and ceremonial treasures.

Does the Bible tell us that King Solomon mined copper? Let us look at what the Bible says:

In Deuteronomy 8:7–9 the Israelites are told that the Lord will bring them

“ … into a good land, a land with streams and springs and lakes gushing out of the valleys and hills; a land of wheat and barley, of vines, figs, and pomegranates; a land of olive oil and honey; a land where you may eat bread without stint, where you will not lack anything; a land where stones are iron, and out of whose hills you may dig coppera.”

In 2 Chronicles 4, and in even greater detail in 1 Kings 7, we learn about the copper objects Solomon ordered for his Temple in Jerusalem. “The weight of the copper used was”, we are told, “beyond reckoning” (2 Chronicles 4:18).

To assist him in constructing his Temple, Solomon relied on Hiram of Tyre, who was “versed in every kind of craftsmanship in copper” (1 Kings 7:14).

Out of copper Hiram fashioned for Solomon two free-standing pillars (called Jachin and Boaz), capitals for the pillars, a great molten sea (a basin supported by 12 copper oxen) which stood outside the Temple, and ten copper lavers, pots and shovels. Hiram also made 200 copper pomegranates to decorate the networks on top of and around the capitals.

The Bible gives the location of the foundry at which the copper objects were cast between Succoth and Zerethan, in the Jordan Valley, almost halfway between the Sea of Galilee and the Dead Sea, a suspiciously long distance from the mines at Timna (1 Kings 7:46).

While the Bible includes extensive descriptions of Solomon’s international commercial activities—he exported wheat and oil and imported gold and silver, as well as ivory, apes and peacocks—there is no mention of copper. If Solomon had mined copper in abundance, we might expect him to pay for the gold and silver he imported with copper.

In one instance, we are told that copper was brought to Israel from outside. In 1 Chronicles 18, we learn that King David defeated Hadad-Ezer King of Zobah when Hadad-Ezer was on his way to set up a monument of victory on the Euphrates River. David took a great quantity of copper from Hadad-Ezer’s cities, Tibbath and Kun. From this copper, the Bible tells us, “Solomon made his Sea of copper, the pillars and the copper vessels” (1 Chronicles 18:8). It is certainly surprising to learn that this copper for the Temple came from somewhere far to the east of Israel—especially if Solomon was mining copper in Israelite mines.

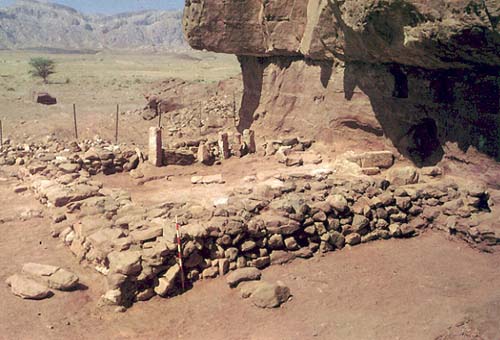

Rothenberg’s archaeological evidence comes from a small mound (45 feet square and 6 feet high) at the base of “Solomon’s Pillars”, a rose-violet scarp that has nothing to do with King Solomon except in name. Rothenberg says that the mound had intrigued him for several years because of three niches in the cliff face immediately above the mound, but below a rock overhang. He suspected that the niches were cultic, as they in fact turned out to be.

The rock overhang blocked the relentless Aravah sun and provided a natural resting place in its shadow. Here Rothenberg began digging through the accumulated debris. On the second day, early Iron Age pottery, copper rings, beads and Egyptian glazed ware appeared. Two days later, a small statue of Hathor, the cow-eared Egyptian goddess of mining, emerged. She was already a well-known figure from discoveries near the Egyptian turquoise mines of southern Sinai. Rothenberg concluded that the small mound covered an Egyptian temple.

During the following months, Rothenberg reports, his small mound disclosed remains from three periods of Timna mining—from the fourth millennium B.C. (the Chalcolithic period), the 14th–12th centuries B.C. (the Egyptian Ramesside period), and the first century A.D. (the Roman period)—all in stratified context. The peak mining activity was associated with strata III and IV. These strata contained large quantities of votive objects manufactured in Egypt: faience beads, alabaster vessels, gold ornaments, glass scarabs, animal figurines, plaques, figures of Hathor, and pottery. Rothenberg also found in these strata a large quantity of locally manufactured copper objects: an unidentified god figure, a mountain sheep with twisted horns, rings, earrings, amulets, tools—and a small serpent once covered with gold that still clung to part of the serpent’s head.

More than 11,000 votive objects were excavated from the Hathor temple of Timna! But the most 020critical objects for dating the temple and the adjunct mining activity were offerings with hieroglyphic inscriptions and cartouchesb containing the names of Egyptian pharaohs.

These inscriptions included the names of all the pharaohs of the 19th and 20th dynasties—from Sethos I (father of Ramesses II), whose reign began in 1318 B.C., to Ramesses V, whose reign ended in 1156 B.C.

The same pottery which was associated with this clearly dated inscribed material was also found scattered in and around the excavated smelting sites at Timna. Some of the pottery was clearly Egyptian. But there were two other pottery repertoires as well which were associated with the same strata. Some reflected a sophisticated culture that used bichrome bowls, jugs and juglets, decorated with large birds and geometric designs. A second included much cruder hand-made pottery. The fancy bichrome ware was identical to pottery found in northwestern Arabia which is associated with the Midianites. The cruder hand-made pottery has been found at various sites in the central Negev. Rothenberg proposes to identify it with the Amalekites. Rothenberg concludes that during the 19th and 20th Egyptian Ramesside dynasties (the 13th century B.C.), the copper mines at Timna were worked by royal Egyptian expeditions who toiled side by side with, or more likely directed, imported Midianite and Amalekite laborers.

Toward the end of the 12th century B.C., the Egyptians withdrew from this area, and the temple mound indicates that the Midianites substituted their own Semitic worship for the Egyptian worship of Hathor. At this time, many Egyptian votive gifts, including sculptures of Hathor and hieroglyphic inscriptions, were thrown out of the shrine area and piled behind the temple wall. A row of mazzeboth or standing stones, clearly reflecting the Semitic nature of the cult, was erected along the inside of one of the temple walls.

Behind the mazzeboth, Rothenberg found a large quantity of heavy red and yellow cloth lying in folded heaps. Another mass of folded material lay inside the opposite wall. The finely woven fabric was made of wool and flax. Rothenberg also discovered two stone-lined post-holes in the floor of the temple. Rothenberg suggests that during its final Midianite phase, the temple was covered by a tent. If so, this is the first tent-sanctuary ever discovered. In the 021naos or shrine of the Midianite temple, Rothenberg unearthed the small gilded copper serpent. This serpent, says Rothenberg “is the first magic object ever uncovered from the time of Moses”. (Compare Exodus 7:10 where Aaron impresses Pharaoh with a magic serpent with Numbers 21:8–9, where we learn that Moses fashioned a magic serpent which could cure snake bites.) The tent-shrine is obviously reminiscent of the tent-shrine which the Israelites carried through the desert (See Exodus 26:1–14, Exodus 26:36).

After the period of the Midianite temple at the end of the 12th century B.C., no evidence of mining activity at Timna appears until the Roman period in the first century A.D.

The pottery which Glueck dated to the Solomonic period can now be securely dated by stratified finds to a period at least 200 years earlier than King Solomon’s reign. Accordingly, there is no evidence that Solomon ever mined copper at Timna—and if not here, there are no other significant sites in the Holy Land to replace it as a candidate. The ambiguous Biblical record should not be read as indicating that King Solomon mined large quantities of copper or that he derived his legendary wealth from this mining activity. Indeed, the fact that King David obtained outside of Israel the copper from which King Solomon later fashioned many of the Temple furnishings (1 Chronicles 18:8) probably indicates that copper was not then mined in Israel. This view is supported by the fact that the Temple fixtures were cast in a foundry located in the Jordan Valley (between Succoth and Zarethan), almost halfway between the Dead Sea and the Sea of Galilee (1 Kings 7:46)—which is nowhere near the copper mines of Timna nor any other copper source in Israel. The author of 1 Kings did not inadvertently omit Solomon’s exports of copper, as Glueck suggests. The omission was intentional. There was indeed copper in Israel’s hills, as God told the Israelites (Deuteronomy 8:9), but, at least on the available archaeological evidence, the Israelites did not mine it.

Rothenberg’s real interest in Timna, however, is not in disproving the legend of King Solomon’s copper mines, but learning more about ancient mining and metallurgy. When Rothenberg began to study mining technology 18 years ago at Timna, 022“There was no one to ask for advice,” he comments. “Archaeologists knew nothing about ancient mining, and miners knew nothing about archaeology.”

It is one of the unique features of the Aravah Expedition, now renamed the Institute of Mining and Metal in the Biblical World, that it has gathered together in the remoteness of the Aravah, people of many disciplines and skills to try to piece together an understanding of ancient mining as it was practiced millennia ago.

Rothenberg’s investigations revealed evidence of extensive mining operations which he divides into three types of mining technology: (1) open cast mining—a kind of stone quarrying technique in which the miner looked for copper-rich nodules in the alluvial surface of the wadi, (2) horizontal gallery mining extending into the white sandstone layers, and (3) deep shaft mining.

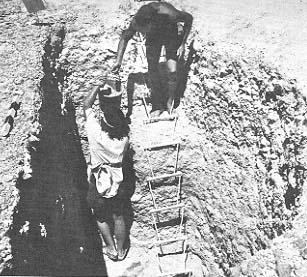

Until 1974 it was generally believed that large scale underground mining was not practiced anywhere before Roman times. The Timna archaeologists, however, suspected that open cut operations alone would not have extracted enough ore to sustain the large scale smelting operation reflected in the smelting camps. Openings to hundreds of horizontal tunnels in the white sandstone layer were well known, but were thought to date to Roman times. Likewise, many shafts—supposedly Roman—had been observed penetrating the top of hills. Rothenberg was convinced that systematic investigation of these shafts and tunnels (or galleries) was essential to unravel the story of ancient mining technology. A team of German engineers and mineworkers was called in in 1974 to tackle the technically difficult task of penetrating ancient rock cuttings, now filled with accumulated silt and debris.

What was learned in 1974 and 1975, Rothenberg says, “changed most of our conceptions about ancient ore extraction.” It was not the Romans who had honeycombed the Timna cliffs with over 7000 mining shafts. The people who excavated this ore from the Timna hills were fourth millennium B.C. Chalcolithic miners. Later—during the 14th to the 12th century B.C., Egyptians working with their technical assistants, the Midianites from Arabia and Amalekites from the Negev, continued the process. The Roman mining operation more than one thousand years after the Egyptian mining was smaller and was located primarily at Beer Ora south of Timna, and in the Sinai.

Chalcolithic people, between 5000 and 6000 years ago, understood how to smelt copper ore; scholars knew this by examining smelting sites strewn with Chalcolithic sherds. But it was a surprise to discover that they had used their stone axes to cut vertical shafts sometimes nine feet deep into the copper rich strata. At the bottom, the shafts connected with horizontal galleries. The ore from these galleries, combined with ore gathered from surface nodules—024malachite, azurite and chalcocite (containing more than 25% copper)—was crushed with flint and stone tools to prepare it for smelting.

On a small hill near the recently-closed modern Israeli copper works, Rothenberg examined the remains of a Chalcolithic smelter which used ore prepared in this way. The ore itself was prepared in a camp at the foot of the hill and was then carried to a furnace at the top where breezes fanned the fires to temperatures between 1150 degrees and 1250 degrees centigrade. This is the earliest copper smelter discovered anywhere in the world. It consists of a simple bowl about four feet in diameter scooped into the hard red sand and then enclosed by a circular wall of compact sandstone. When the smelter was fired, the copper separated from the other minerals and, because it was heavier, sank to the bottom of the furnace. In the Chalcolithic furnace, the copper was still mixed with slag at the end of the process. In order to remove the copper-slag mixture, the upper walls of the furnace had to be broken apart. Then the mixture was broken up with a hammer and the pure copper globules picked out. Primitive though these 5000-year-old smelters were, the result was refined copper that was over 97%, and some times 99%, pure—as determined by assay of copper globules found in the slag.

Almost 2000 years passed after the Chalcolithic period before the mining at Timna again left clear physical remains. The Egyptian (Ramesside) mining enterprise (14th–12th centuries B.C.) not only brought a new cast of characters, but also introduced new developments in metallurgical techniques.

The Egyptians left very large slag heaps, indicating that their mining activity was on a far larger scale than that of the Chalcolithic people. In these slag heaps Rothenberg found an abundance of datable pottery and metallurgical tools.

Rothenberg also found the components of a highly-integrated commercial enterprise—large smelting furnaces, small scale crucible furnaces, cisterns and workshops. The sophistication of these smelting furnaces rivals those of medieval Europe, the excavator stated. These furnaces were similar in shape to their Chalcolithic predecessors, but they were different in several respects. Although essentially bowls dug into the sand, the Egyptian furnaces were lined with clay. They were also fitted with a tuyere, a clay tube about 4 inches in diameter which passed through the wall of the furnace. Air was blown by a bellows through the tuyere into the furnace. The nozzle of the bellows was protected from the intense heat by a shield which was discarded after each smelting operation. Many of these shields were found strewn about the site. In front of each smelter a stone-lined tapping pit was built. The slag flowed into the tapping pit from a hole in the furnace wall just above the level of the molten copper; the molten copper remained in the furnace at a lower level. Any copper globules that remained in the slag would be extracted after it reached the tapping pit. The pure bun-shaped copper ingot remained on the bottom of the furnace and was probably removed with the aid of a so-called plunging rod inserted into the molten copper. When the copper hardened around the plunging rod, the ingot could be lifted out. By removing the hot copper ingot in this way, new ore could be fed into the still hot furnace. Thus, a continuous operation was possible without cooling the furnace. Rothenberg estimates that a typical furnace produced up to 125 pounds of copper a day. Assay of the Ramesside copper showed it to be 89–92% pure—not quite up to the Chalcolithic standards of 2000 years earlier!

For many years after the investigations of the Ramesside smelting camps, the question remained as to how the Ramessides collected so much ore. Open cast mining—surface collection of copper nodules—was surely unable to provide such large 025quantities of ore. Finally in 1976, Rothenberg found evidence that Egyptian and Midianite miners had extensively tunneled into the white sandstone layers of the Timna cliffs in a complex system of vertical shafts and horizontal galleries. One of these shafts penetrated to a depth of over 100 feet where it intersected a horizontal tunnel. Chisel marks on the walls of the tunnels as well as the chisels themselves reflect the enormous effort that went into this mining operation and also help date it. Rothenberg excavated several types of Ramesside shafts and galleries. Some were ventilating galleries, parallel to and connected with the larger galleries in which the miners worked. Some shafts were probes seeking the best mining vein.

Many of the galleries may now be entered directly on the side of the hills. But Rothenberg believes that these openings are the result of relatively recent erosion of the hillside. And that originally these galleries could be entered, only from vertical connecting shafts. An unexpected conclusion, perhaps. But the unexpected is what we have come to expect from the studies of Beno Rothenberg.

Working for almost two decades among the monumental sandstone formations of Timna, Rothenberg has illuminated ancient copper mining and metallurgy as no one else before him. We now know not only that “out of these hills you may dig copper” (Deuteronomy 8:9), we also know how it was done technologically—but we have no evidence at Timna that it was done by the Israelites.

(For further details, see B. Rothenberg, Timna, Thames and Hudson, (1972). However, this article contains much that has been discovered since the publication of Rothenberg’s book.)

For almost two decades and still continuing, Israeli archaeologist Beno Rothenberg has investigated the Timna Valley—called in Arabic wadi Mene’iyeh and known to thousands of visitors as “King Solomon’s Mines”. At first Rothenberg came almost alone to this isolated spot in the Negev about 20 miles north of Eilat, but in recent years he organized an international team of miners, geologists, physicists, historians and engineers. Rothenberg and his team have probed slag heaps and smelting camps under a blazing sun that often reaches 120 degrees fahrenheit. In the past three years, Rothenberg penetrated seemingly endless ancient mine shafts and […]

You have already read your free article for this month. Please join the BAS Library or become an All Access member of BAS to gain full access to this article and so much more.

Already a library member? Log in here.

Institution user? Log in with your IP address or Username